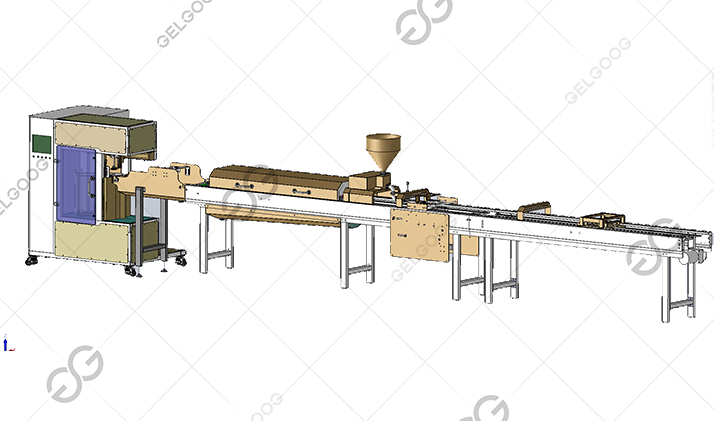

This Vietnamese spring roll production line is specially customized for the production of Vietnamese spring rolls, the fillings are usually meat or vegetables, the output of a single row is about 1000-2000 pcs/h. According to the production requirements of different customers (rice paper size, finished product size, output, etc.), customized solutions are provided.

This Vietnamese spring roll production line is specially customized for the production of Vietnamese spring rolls, the fillings are usually meat or vegetables, the output of a single row is about 1000-2000 pcs/h. According to the production requirements of different customers (rice paper size, finished product size, output, etc.), customized solutions are provided.

This rice paper spring roll machine is made of 304 stainless steel except for special parts, and the electrical components are made of famous brands to ensure that customers can work continuously for a long time.

In order to better control the quality of rice paper spring rolls, the Vietnamese spring roll production line is equipped with water spraying device, steamer and filling delivery device with precise control technology to ensure the uniformity of rice paper and the consistency of the amount of filling.

Vietnamese Spring Roll Production Line Features: