This potato chips production line adopts fresh potato as raw material, which can be used to produce potato chips of about 1.5mm, and the actual thickness can be customized according to the production requirements. The main potato chips production process includes cleaning and peeling, slicing, blanching, deep-frying and so on. The production capacity of the potato chips processing equipment ranges from 100-2000kg/h. It can meet different scale of production.

This potato chips production line adopts fresh potato as raw material, which can be used to produce potato chips of about 1.5mm, and the actual thickness can be customized according to the production requirements. The main potato chips production process includes cleaning and peeling, slicing, blanching, deep-frying and so on. The production capacity of the potato chips processing equipment ranges from 100-2000kg/h. It can meet different scale of production.

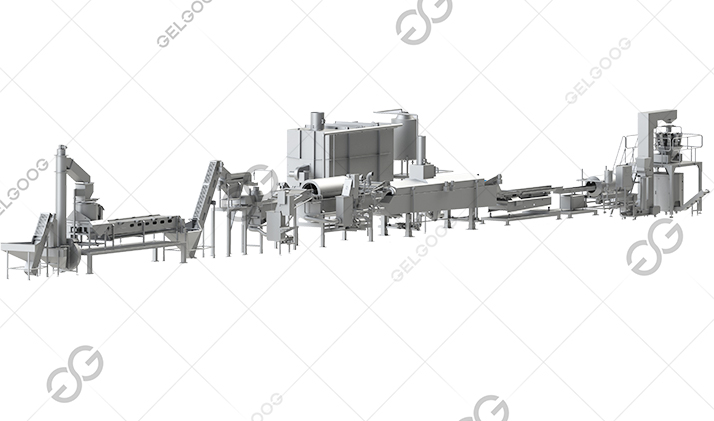

Potato chips production line adopts fully automatic continuous production. Taking fresh potato as raw material, it can provide potato chips production including: cleaning, peeling, slicing, washing starch, draining, hot bleaching, deep-frying, draining oil, seasoning, packaging and so on. The production line is equipped with filtration system, de-oiling system, flavoring system, cooling system and so on, with mature supporting. The potato chips production line can be customized according to customer needs, according to the output can choose to match different equipment models.

Potato Chips Processing Equipment Advantages:

Processing Materials:

The potato chips processing equipment is suitable for processing different varieties of potatoes. Such as: Agria, LadyAmarilla, etc.

Application Field

Potato chips production line is suitable for various food processing enterprises, especially medium and large potato chips manufacturers. Through this production line, the enterprise can efficiently produce high-quality potato chips to meet the market demand and improve competitiveness.