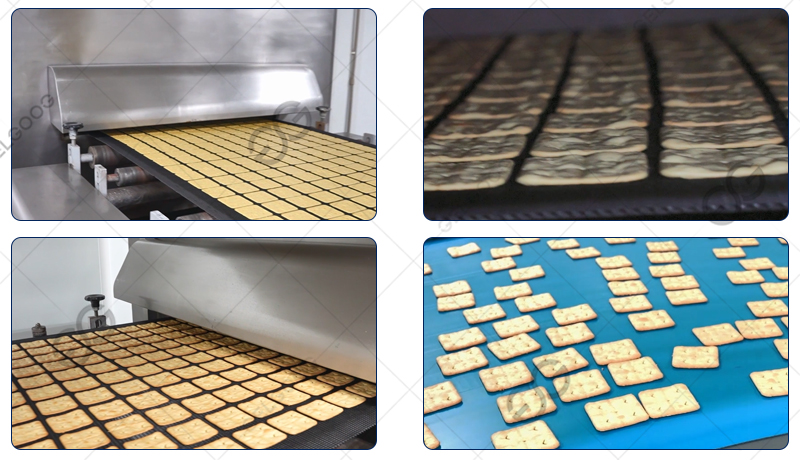

The industrial tunnel oven adopts the internationally accepted tunnel structure and design, with a temperature control range of 0-250℃ and a baking time setting of 8-80 minutes. It can increase circulating air and temperature proportional control and can be used for bread, cakes, moon cakes, cookies, biscuits, nuts, vegetables, etc.

Biscuit Baking Tunnel Oven Features:

- Sturdy and durable: The industrial tunnel oven is made of high-quality materials, and the tunnel structure is elastic and sturdy, and can withstand long-term use without failure.

- Good thermal insulation performance: The tunnel design takes thermal insulation performance into consideration, which can effectively reduce energy loss, improve energy utilization and reduce use costs.

- Accurate temperature control: Equipped with PID temperature control module, it can accurately control the temperature inside the oven, ensure the temperature stability during the biscuit baking process, and avoid the impact of temperature fluctuations on biscuit quality.

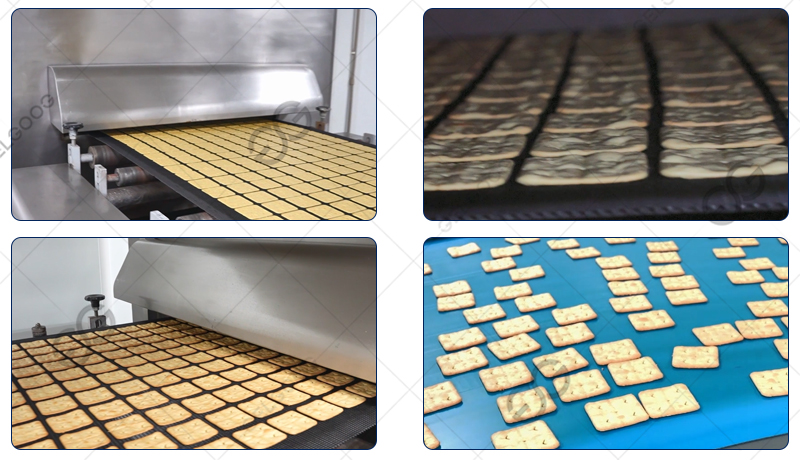

- Efficient and uniform heat distribution: Through continuous improvement, based on the test data of gas biscuit baking tunnel oven, efficient and uniform heat distribution can be achieved in the furnace, ensuring that the biscuits are heated evenly during the baking process and achieving better baking results.

- Consistent baking results: Due to precise temperature control and uniform heat distribution, the industrial tunnel oven can ensure the consistency of biscuit baking, so that each batch of biscuits has the same taste and quality to meet customer requirements.

Biscuit Baking Tunnel Oven Structure:

- Transmission system: adopts self-lubricating conveyor chain, low noise and wear-resistant advantages can withstand high temperature 500 degrees, frequency conversion motor with stable performance and high durability, the speed is 10 times adjustable, the time error is about 2 seconds. Conveyor belt partition adopts thickened steel plate with special structure sealing design, which is favorable for more uniform heat circulation and ensure the baking effect.

- Temperature control system: over-temperature limit delay action function, limit temperature, delay time parameters can be freely set to achieve PID + ON.OFF function, to ensure temperature control in ± 2.5 ℃, the normal temperature fluctuations ± 1 ℃.

- Heat circulation wind system: the upper part of the furnace chamber hot air from the convection windmill mandatory pumping to the top, the bottom of the furnace chamber hot air from the convection fan mandatory pumping back by the convection windmill so that the hot air through the convection duct mounted circulation operation, to achieve the desired combustion effect.